Still can't find the component you need in our extensive product range? No problem! We also offer extensive options for custom-made products. We can supply tailor-made components that are precisely matched to your requirements.

- Turned parts

- Plastic parts according to drawing

- Reworking

- Finishing

- Thread locking

- Assembly

- Samples and prototypes

Thanks to almost 60 years of experience and efficient processes, we offer fast delivery of all products from the initial sample to series production – as well as end products of the highest quality. Custom-made products from ETTINGER offer a fast route to market for your in-house developments.

Special designs from ETTINGER

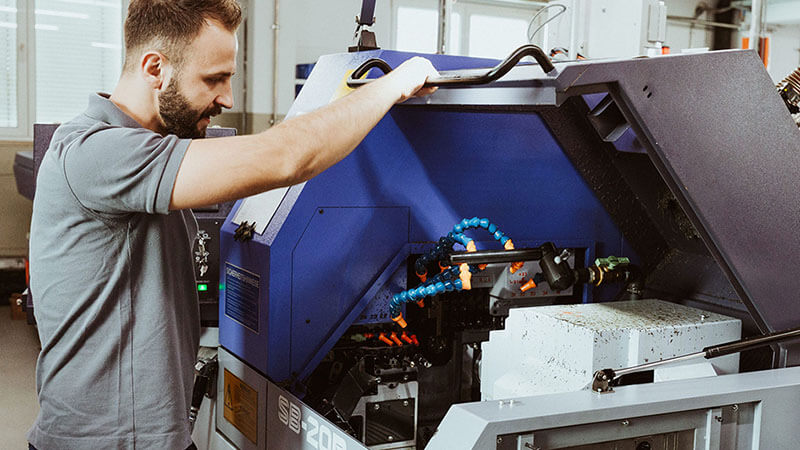

Turned parts: Proudly "Made in Bavaria".

| Materials | Dimensions | Surface coatings |

|---|---|---|

|

|

|

Our expert team of engineers, technicians and specialists ensures that our turned parts are perfect in every detail. We are at your disposal with our profound expertise and many years of experience. We look forward to receiving your inquiry!

Plastic parts according to drawing: Precisely designed, efficiently produced.

During production of your plastic parts according to drawing, you benefit from our broad supplier network of highly specialized, world-leading manufacturers with their own development departments, tool shops for even the most challenging tasks, and state-of-the-art machinery.

Using injection molding and other forms of plastics processing, we manufacture plastic components that are precisely matched to your specific application or assembly.

| Areas of application | Available designs | Materials |

|---|---|---|

|

|

|

A range of different colors is also available.

Contact us for modifications of standard parts or custom sizes and dimensions. Our experienced team will be happy to advise you!

Special designs from ETTINGER

Reworking: If it doesn't fit, we'll make it fit!

- Shortening of supplied screws

- Additional drill holes

- De-coating and re-coating of already surface-treated parts

- Soft annealing

- Milling

- … or other applications

Special designs from ETTINGER

Finishing: Great results, strong products.

- Corrosion protection

- Electrical isolation

- Improved electrical conductivity

- Improved solderability

- Improved paintability

- Decorative finishing

Galvanic coating in accordance with DIN EN ISO 4042

In galvanic surface treatment, metals (zinc, copper, nickel, tin) or metal alloys (zinc-nickel, zinc-iron, zinc-cobalt) are deposited on the steel surface by means of an electric current. The color of the metal layer can then be changed via passivation or sealing.

Advantages:

- Very good corrosion protection

- Low layer thickness (3 – 15 μ)

- No recutting of threads necessary

- Color stability

Chemical nickel-plating

Chemical treatment involves applying an electroless chemical coating consisting of an aqueous nickel salt solution. Due to the electroless process, non-conductive parts can also be coated.

Advantages:

- Excellent corrosion protection

- Uniform layer distribution even on internal surfaces with narrow layer tolerances

- Coatings follow all contours perfectly without edge build-up

- Coating thickness can be easily adjusted

- Wear resistant

- Good resistance to chemicals

- High degree of hardness

We can fulfill almost every customer request – and would be glad to advise you!

Special designs from ETTINGER

Assembly: Perfectly arranged, securely packaged.

We are also happy to provide you with sets based on your individual requirements and can put together product combinations to suit your needs.

Special designs from ETTINGER

Thread locking: Always a strong connection.

Even under high dynamic loads, as captive thread components they provide reliable protection against unintentional loosening and release of the screw connection.

Almost any threaded part can be prepared for safe use, even in extremely low and high temperature ranges. We offer:

Thread locking based on microencapsulated adhesive

- 2-component coating provides permanently bonded anti-loosening protection

- Dry, non-slip, lacquer-like coating, which only releases its properties during assembly through pressure and/or shear stress

- The screwed parts can NOT be re-used multiple times

Advantages:

- Bonding and sealing function

- Resistant to oil and grease

- No assembly risk in cured condition

- Prevents loosening in case of vibrations

Thread locking via polyamide coating with a clamping effect

- Polyamide coating of bolts and screws

- Dry, non-slip coating that generates high surface compression (frictional contact) and thus a clamping effect

- The screw can be loosened and retightened multiple times

- A selection of clamping screws can be found here

Advantages:

- Multiple reuse

- Highly resistant to solvents

- Low sensitivity to moisture

Some coatings provide additional sealing as well as a captive effect.

Especially in automated production processes, this one-component solution provides real added value. We would be delighted to look at your individual requirements and show you the available options. Send us your inquiry today!

Samples and prototypes: Sound advice, fast delivery.

Thanks to high stock availability of our standard range it is usually possible to provide you with samples of our standard products at short notice – so you can perform your own tests based on your specific application.

Perhaps your requirements are rather more specific, but you do not have your own development capability or procurement source? We will gladly work out a solution with you! Simply send us your requirements as a dimensioned drawing, sketch or description. In most cases, we can realize prototypes of your specific components with short lead times as custom designs.

We would be happy to send you a non-binding quotation! Get in touch now!